The Crusader Deluxe Conditioner Water Softener

Automatic & Metered Control

Fully automatic; easy-to-use and maintain

Improved Soap Efficiency

Save up to 80% on soap and cleaning products

Water Heater Protection

Increased lifespan and energy efficiency

Chlorine Control

No more chlorine tastes or odors

Hard Water Scale Control

Protect your pipes and infrastructure

Laundry Protection

Make your clothes softer, whiter, and brighter

Dishwasher Protection

Reduced dish spottiness & no hard water film

Heavy Metal Control

Heavy metals, iron, rust, & sediment protection

What’s Included & How It Works:

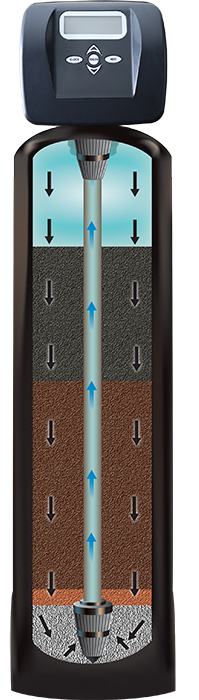

Operation of the Softener

Hard water contains dissolved minerals and metals in the form of Calcium (Ca), Magnesium (Mg), Iron (Fe), Copper (Cu), & Zinc (Zn). Reduction of these contaminants is accomplished by softening the water through an ion-exchange process. As water flows through the mineral tank, the contaminants become attached onto and inside the resin. Over a period of time, the resin will become saturated with contaminants, and the softener will require regeneration using a sodium or potassium brine solution.

Softening Media – AquaPro 500-2 Hybrid

The exchange media is a high quality, FDA certified, commercial-grade strong acid hybrid (Cation) Functional Matrix resin with a very high whole bead count and no color throw. It’s physically hard and is moderately chlorine resistant. Hybrid media is engineered to encompass all the attributes of 500-1 softening media in addition to leveraging all functions of 500-2 Conditioning media when working together with ProGuard or ProGuard Plus. The media combines high operating capacity with excellent chemical and physical stability for a long, dependable life. An NSF-approved clarifying media is included to provide crystal-clear water. Food-grade gravel under-bedding ensures uniform flow, minimal pressure drop, and excellent performance.

Controller/Meter

Regeneration of the system is initiated by a simplified digital control, which electronically meters softened water flow and makes decisions to regenerate based on water consumption and program settings. Salt dosage is controlled differentially to maximize the softener’s efficiency.

Regeneration

These softener models are controlled electronically. A fully programmable microprocessor controls Tank Fill, Percolation, Ion Exchange, Double Backwash, Rapid Rinse, and Return-To-Service cycles.

Control Valve

A hydraulically balanced, -coated piston slides effortlessly through seals & spacers. All parts in the waterway are either coated brass or composite Noryl® materials to ensure a long and reliable service life.

Resin Tank

All softener models feature a non-corrosive fiberglass tank with a one-piece thermoplastic inner liner. The tank has a maximum working pressure of 90 psi and a working temperature up to 120°F. The tank is approved by NSF, UL, and the FDA. It also meets WQA Standard S-100. All fiberglass tanks carry a limited lifetime warranty.

Brine Tank

A high capacity brine tank is included as part of this system. The brine tank is a combination brine maker and salt storage vessel and is made of tough, high-density polyethylene. Larger tanks are available for extra salt storage capacity, if required. Brine tanks 24” diameter and smaller feature a grid plate for maximum saturation of brine.

Brine System

Brine refill is automatically controlled by the computer to provide the exact amount of brine required for each regeneration. The Brine System has a float and safety valve shut-off, which minimizes the chance of overflowing the brine tank. All units are equipped with an air check.

Product Specifications Table:

Deluxe Conditioner Softener Models | CS-D-35 | CS-D-50 | CS-D-72 | CS-D-96 | CS-D-130 |

Maximum System Capacity (Grains-CaCO3) | 35,000 | 50,000 | 72,000 | 96,000 | 130,000 |

Default System Capacity (Grains-CaCO3) | 28,400 | 42,600 | 56,800 | 85,200 | 113,600 |

High Efficiency Capacity (Grains-CaCO3) | 22,000 | 33,000 | 44,000 | 66,000 | 88,000 |

Maximum Salt Used Per Cleaning (lbs) | 15 | 22 | 30 | 45 | 60 |

Default Salt Used Per Cleaning (lbs) | 9 | 14 | 18 | 27 | 36 |

High Efficiency Salt Used Per Cleaning (lbs) | 6 | 9 | 12 | 18 | 24 |

Peak Flow Rate (gpm) @ 75 psi inlet, 25 psi drop | 21 | 22 | 23 | 25 | 28 |

Service Flow Rate (gpm) @55 psi inlet, 15 psi drop | 13 | 14 | 16 | 20 | 25 |

Dimension A - Overall System Height | 62" | 62" | 60" | 62" | 73" |

Dimension B - System Piping Height | 56.09" | 56.09" | 54.09" | 56.09" | 67.09" |

Dimension C - Pressure Vessel Height | 54" | 54" | 52" | 54" | 65" |

Dimension D - Pressure Vessel Diameter | 10" | 10" | 12" | 13" | 14" |

Brine Tank Dimensions (L x W x H) (Inches) | 14 x 14 x 34 | 14 x 14 x 34 | 18 x 40 | 18 x 40 | 24 x 50 |

Total Space Required (L x W x H) (Inches) | 14 x 25 x 62 | 14 x 25 x 62 | 18 x 32 x 60 | 18 x 33 x 62 | 24 x 40 x 73 |

Shipping Weight (lbs) | 100 | 130 | 200 | 245 | 350 |